Discount Price Gas Turbine - General metal workpiece processing – Aierfu

Discount Price Gas Turbine - General metal workpiece processing – Aierfu Detail:

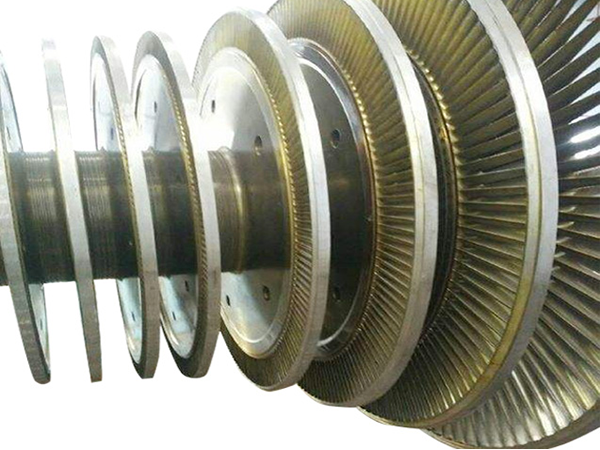

product presentation

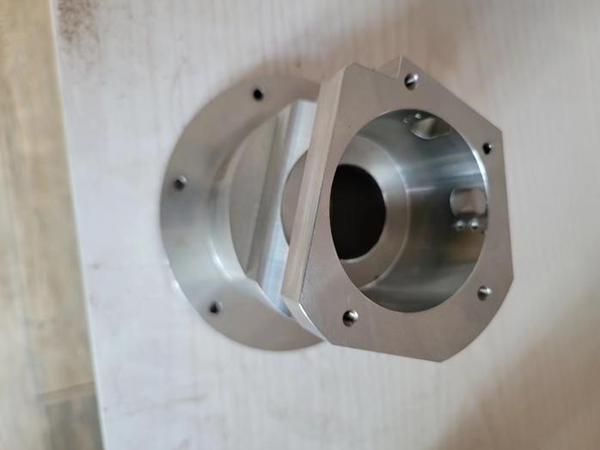

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Cold machining is characterized by the high-speed relative movement between the clamping tool used and the workpiece or tool to be cut, which is the product forming. Cold working can be divided into cutting and pressure machining according to the difference of processing methods. In metal technology, it is corresponding to hot working. Cold working refers to the processing technology that can make metal plastic deformation at a temperature lower than the recrystallization temperature, such as cold rolling, cold drawing, cold forging, stamping, cold extrusion, etc. Cold working has great resistance to deformation, which can improve the hardness and strength of the workpiece by means of work hardening while forming the metal.

The company has three imported turning milling compound five axis machining centers, four imported five axis linkage machining centers, four full-automatic CNC lathes, several other gantry boring machines, drilling machines, planers and other processing equipment, as well as three Hikscon CMMs, GOM scanners and a number of auxiliary testing equipment, with a strong ability to process turbine blade molds, automobile supports and general mechanical workpieces.

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for Discount Price Gas Turbine - General metal workpiece processing – Aierfu , The product will supply to all over the world, such as: Sydney, Spain, Bahamas, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of human-oriented and faithful service, with an aim to gain global recognition and sustainable development.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.