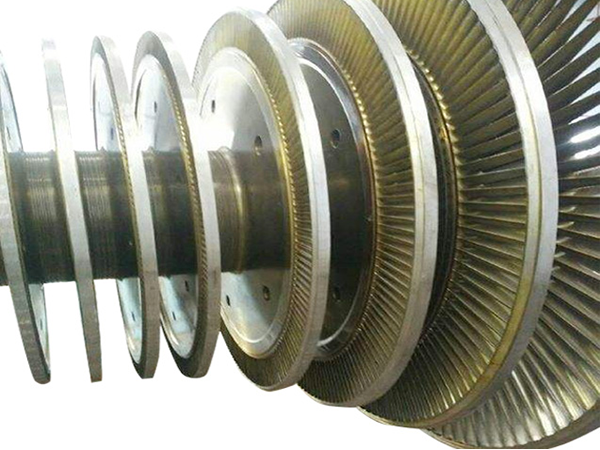

Factory Promotional Single Blade Turbine - General metal workpiece processing – Aierfu

Factory Promotional Single Blade Turbine - General metal workpiece processing – Aierfu Detail:

product presentation

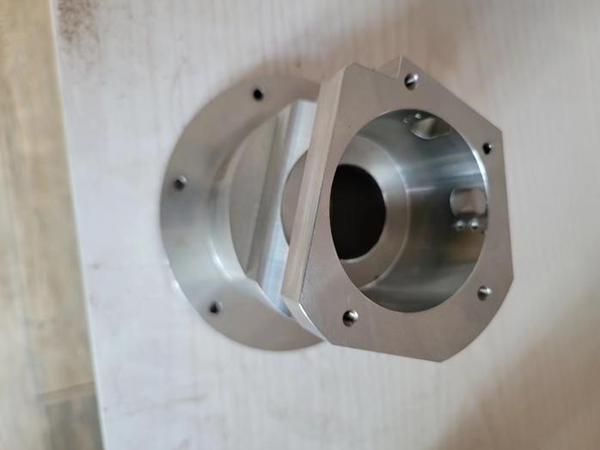

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Cold machining is characterized by the high-speed relative movement between the clamping tool used and the workpiece or tool to be cut, which is the product forming. Cold working can be divided into cutting and pressure machining according to the difference of processing methods. In metal technology, it is corresponding to hot working. Cold working refers to the processing technology that can make metal plastic deformation at a temperature lower than the recrystallization temperature, such as cold rolling, cold drawing, cold forging, stamping, cold extrusion, etc. Cold working has great resistance to deformation, which can improve the hardness and strength of the workpiece by means of work hardening while forming the metal.

The company has three imported turning milling compound five axis machining centers, four imported five axis linkage machining centers, four full-automatic CNC lathes, several other gantry boring machines, drilling machines, planers and other processing equipment, as well as three Hikscon CMMs, GOM scanners and a number of auxiliary testing equipment, with a strong ability to process turbine blade molds, automobile supports and general mechanical workpieces.

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with Factory Promotional Single Blade Turbine - General metal workpiece processing – Aierfu , The product will supply to all over the world, such as: Denmark, Luxemburg, Sri Lanka, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a people-oriented, meticulous manufacturing, brainstorm, construct brilliant organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.