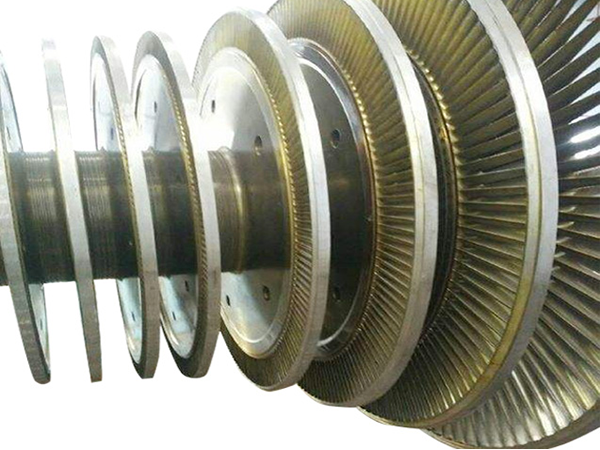

Hot Selling for Air Knife Nozzle - Gas turbine custom superalloy turbine blades – Aierfu

Hot Selling for Air Knife Nozzle - Gas turbine custom superalloy turbine blades – Aierfu Detail:

Gas turbine blade

The company has a good quality control team, excellent testing technology, advanced manufacturing and testing equipment and a rich experienced technical team. The company has a good reputation and has long-term good cooperation with well-known manufacturers at home and abroad.

The main features of gas turbine blades are:

1. The material contains expensive superalloy elements;

2. Poor processing performance;

3. Complex structure, high precision and surface quality requirements;

4. There are many varieties and quantities;

The above characteristics of blades determine the development direction of blade processing and production: organize specialized production; Advanced blank manufacturing process with little or no cutting is adopted to improve product quality and save high temperature resistant materials; Adopt automatic and semi-automatic efficient machine tools, organize automatic production lines for flow production, and gradually adopt numerical control and computer technology for processing.

As we all know, blades in gas turbines are the “heart” of turbomachinery and the most important parts in turbomachinery. Turbine is a kind of rotating fluid power machinery, which directly plays the role of transforming the heat energy of steam or gas into mechanical energy. Blades generally work under high temperature, high pressure and corrosive medium. The moving blades also rotate at a high speed. In large steam turbines, the linear velocity at the top of the blade has exceeded 600m/s, so the blade also bears great centrifugal stress. The number of blades is not only large, but also the shape is complex, and the processing requirements are strict; The processing workload of blades is very large, accounting for one quarter to one third of the total processing capacity of steam turbines and gas turbines. The

machining quality of blades directly affects the operation efficiency and reliability of the unit, and the quality and life of blades are closely related to the machining method of blades. Therefore, the blade processing method has a great impact on the working quality and production economy of turbine machinery.

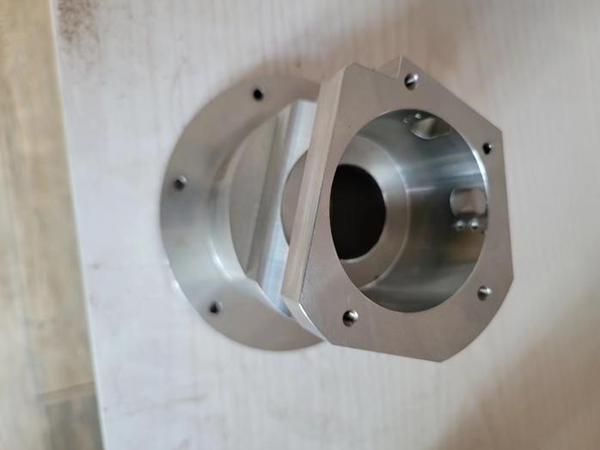

Product detail pictures:

Related Product Guide:

It adheres on the tenet Honest, industrious, enterprising, innovative to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Hot Selling for Air Knife Nozzle - Gas turbine custom superalloy turbine blades – Aierfu , The product will supply to all over the world, such as: Austria, South Africa, Montreal, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!