OEM Supply Wind Generator Blades - General metal workpiece processing – Aierfu

OEM Supply Wind Generator Blades - General metal workpiece processing – Aierfu Detail:

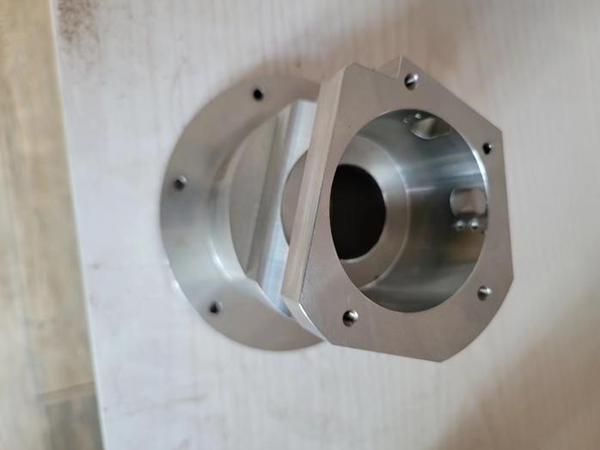

product presentation

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Mechanical cold working usually refers to the cutting method of removing materials by workers operating the machine tool, that is, cutting tools are used to remove excess metal layers from metal materials or workpieces, so that workpieces can obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as turning, drilling, milling, planing, grinding, broaching, etc.

Cold machining is characterized by the high-speed relative movement between the clamping tool used and the workpiece or tool to be cut, which is the product forming. Cold working can be divided into cutting and pressure machining according to the difference of processing methods. In metal technology, it is corresponding to hot working. Cold working refers to the processing technology that can make metal plastic deformation at a temperature lower than the recrystallization temperature, such as cold rolling, cold drawing, cold forging, stamping, cold extrusion, etc. Cold working has great resistance to deformation, which can improve the hardness and strength of the workpiece by means of work hardening while forming the metal.

The company has three imported turning milling compound five axis machining centers, four imported five axis linkage machining centers, four full-automatic CNC lathes, several other gantry boring machines, drilling machines, planers and other processing equipment, as well as three Hikscon CMMs, GOM scanners and a number of auxiliary testing equipment, with a strong ability to process turbine blade molds, automobile supports and general mechanical workpieces.

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for OEM Supply Wind Generator Blades - General metal workpiece processing – Aierfu , The product will supply to all over the world, such as: Victoria, Bahamas, San Diego, Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!