Turbine stationary blade diaphragm

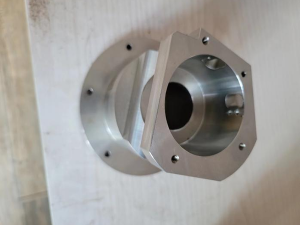

During the diaphragm manufacturing process, the key problem is the connection between the stationary blade and the diaphragm body and the outer ring. The technical requirements are all put forward to this problem. The connection between the stationary blade and the diaphragm body and the outer ring must have sufficient strength, the diaphragm steam passage must have correct cross-sectional shape and area, the pitch circle should be concentric with the diaphragm center, the inlet and outlet edges of the stationary blade should be on the same plane, and the processed diaphragm should have sufficient smoothness, To ensure good air tightness. The plane of the steam outlet side of the outer ring of the diaphragm is parallel to the plane of the steam outlet side of the stationary blade to ensure the tight connection with the cylinder.

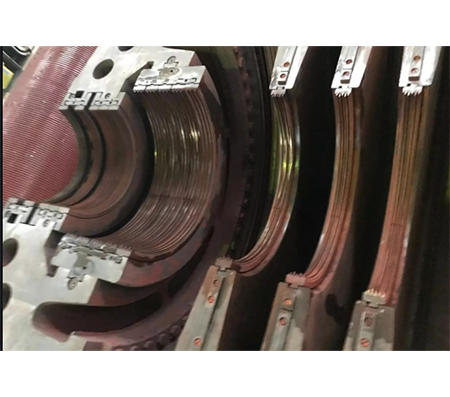

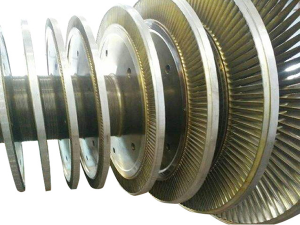

Purpose of steam turbine diaphragm: it is used to fix the stationary blades and form the partition walls at all levels of the steam turbine. It is mainly composed of the diaphragm body, the stationary blades and the outer edge of the diaphragm. The steam turbine diaphragm is mainly installed in the diaphragm groove on the inner wall of the cylinder or installed on the cylinder by means of the diaphragm sleeve. As shown below:

There are more than 20 technical processing workers in the partition workshop of our company. These workers have been engaged in the professional manufacturing and processing of partitions for more than ten years, and are equipped with professional testing equipment: direct reading spectrometers, ultrasonic flaw detectors, special internal and external diameter micrometers, etc. In order to ensure the quality and production capacity of the separator and meet the delivery needs of customers, the company has various vertical lathe, automatic gas shielded welding machine and large-scale numerical control equipment, such as 1.6m, 2.5m and 4m.